Early detection of fires in factory equipment by IoT temperature monitoring

Predictive maintenance of equipment

Many equipment are in operation in factories and on the production line.

There is no problem if these equipment are operating normally, but if they break down, the production line will stop, causing a great loss.

Predictive maintenance is to predict in advance that equipment will break down and take countermeasures.

Early detection of rapid temperature rise due to failure

A further problematic case is that a sudden temperature rise due to equipment failure and causes a fire.

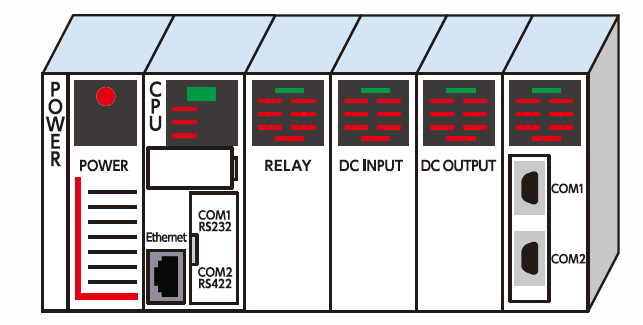

Let’s take a PLC as an example.

Factory equipment such as PLCs are housed in racks, usually with multiple large racks lined up.

For example, if one of these devices breaks down, a fire alarm in the room will alert you.

However, it may be too late.

In other words, there is a need to detect the fire earlier than the alarm after the fire has spread to some extent.

Installation of temperature sensor in the rack

By utilizing IoT, it is possible to detect the temperature rise of each device at an early stage.

Install a sensor node containing a temperature sensor in each rack.

The temperature information is wirelessly aggregated in the Gateway, and the temperature is constantly monitored remotely.

This makes it possible, for example, to detect an abnormality based on the temperature data obtained from the temperature sensor and issue an alarm earlier when a sudden temperature rise occurs due to a device failure.

In other words, you can detect signs early before the fire spreads.

System configuration with Tele-Sentient

We have an experience of introducing monitoring systems for disaster prevention applications in IoT that utilize temperature sensors in actual factories.

By using Tele-Sentient, it is possible to configure such a system by Sensor-Mate with a temperature sensor.

If you are interested, please feel free to contact us.