Monitoring of degradation of structures

Utilization of IoT for deterioration diagnosis

As the number of old structures is increasing, there is an effort to use IoT to screen for deterioration diagnosis by catching signs of abnormalities in structures.

In many countries, many infrastructures were built decades ago, and many have near-life.

It is necessary to inspect them on an annual basis, but it will be a very effective system if data can be accumulated by fixed point observation and constant monitoring using IoT and the degradation status can be primarily screened.

The structures to be diagnosed are bridges, dams, tunnels, river structures, steel towers, etc., and the diagnostic sites are diverse, such as degradation of concrete, reinforcing bars, and piping.

Current method of degradation diagnosis

What kind of investigation is being conducted in the current degradation diagnosis?

The following are the main diagnostic methods used.

Visual inspection

- Visual inspection using human eyes (cracks, peeling, etc.)

- Visual inspection with a camera

Non-destructive inspection

- Structure thickness inspection (ultrasonic waves, impact elastic waves)

- Reinforcing bar inspection (cover depth, X-ray)

- Compression strength estimation test (hammer impact, float range, degree, etc.)

Chipping inspection

- Reinforcing bar corrosion inspection in concrete

- Neutralization test (survey with phenolphthalein solution)

- Cover thickness, corrosion status

Core-less inspection

- Extraction of sample from concrete for inspection (neutralization, compressive strength, sulfuric acid corrosion, etc.)

Corrosion environment survey

- Water quality survey

- Hydrogen sulfide concentration survey

This is a picture of our structure measuring the temperature of a structure using a simple far-infrared thermography.

Thermography can be used to visualize high and low wall temperatures, and it is said that this temperature data can be used to understand the state of degradation.

It seems that such temperature diagnosis is also used in the actual field.

Problems of degradation diagnosis

In the actual deterioration diagnosis, various inspections are conducted, and it is said that there are the following problems.

Screening

- Even if several to dozens of places are measured by visual inspection and sampling inspection, there are an increasing number of cases where degradation or accidents occur in parts that were not initially expected.

- It costs a huge amount of money to perform a full-scale inspection.

High-cost incidental work

- Costs other than inspection such as scaffolding and mining.

Confirmation of degradation degree

- Depends on the skill of the inspector.

- It is required to judge the degree of degradation by numerical values.

Degradation factor estimation

- Establishment of technology to estimate the cause of degradation.

Notification in case of abnormality

- In addition to prevention before an accident occurs, grasping signs of occurrence and timely notification.

Benefits of using IoT

What are the benefits of using IoT in degradation diagnosis?

The main advantage is that you can perform a primary screening for degradation.

As a result, if the result shows that repair work is likely to be required, you can move to the action of investigating the details using a measuring device.

In other words, in addition to the detailed inspections that have been carried out once every one to several years, even if the accuracy is not so high, by constantly monitoring, timely detection of deteriorated abnormal conditions and countermeasures is possible to detect infrastructure abnormalities that lead to serious incidents at an early stage.

Early detection of signs of degradation by simple screening.

Digitization of sensing data to estimate degradation factors.

Discovery of signs of abnormalities and timely notification.

These are the benefits of using IoT.

Sensors used in IoT utilization for degradation diagnosis

Many types of sensors are needed, such as acceleration sensors, strain sensors, current sensors, and sound wave sensors.

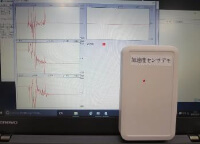

We have been constructing a demo system that can monitor the vibration results collected by Gateway by connecting an acceleration sensor to the sensor node, performing wireless transmission, and explaining it at exhibitions.

By analyzing this, it is possible to understand the results such as vibration of the structure.

Features of Tele-Sentient

Tele-Sentient has built a mechanism that allows you to select and connect many types of sensors by sensor plug and play.

If you are interested, please feel free to contact us.